Clean air in food and beverage production

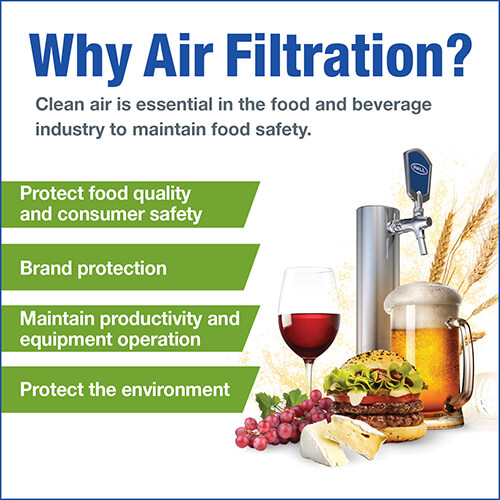

Compressed air and gas filtration is a crucial part of food and beverage production. Having the right air and gas filtration solutions can provide brand protection, meet consumer safety standards and ensure smooth equipment operation.

Compressed air and other industrial gases, typically nitrogen or carbon dioxide, are used in a variety of food and beverage processing and packaging applications, either directly contacting products, ingredients, packaging materials and equipment surfaces, or for pneumatically-driven process operations. To safeguard products and manufacturing processes, removing airborne contaminants, including water droplets or vapors, oil vapors, smoke, allergens, dust, and other particles, microorganisms (e.g, pathogens, viruses and bacteriophages) is critically important.

Various air filtration technologies are available depending upon the type of impurities to be removed and the nature of the applications. Meeting specific air quality requirements to satisfy industry, regulatory and company guidelines is the goal of compressed air filtration. It is important to understand the requirements so that appropriate and cost-effective filtration is selected.

Depending on whether applications are for direct or indirect food contact use, national and international regulations apply. Pall has over 60 years of experience in specifying air filtration products to meet your food and beverage requirements including final filtration and prefiltration.

To learn more about final or sterile air filtration and prefiltration, please select an application below.

-

Air & Gas Pre-filtration

-

Sterile Air & Gas Filtration

Air pre filtration removes microorganisms from air or other gases to prevent airborne microbial contamination that could prematurely block the final membrane filters. Pall offers the following different options for air and gas prefiltration, depending on the specific customer requirements. The Profile® Star pleated depth filter is excellent for applications where there are a wide range of particles. Alternatively for higher temperature applications, Ultipor® GF Plus and Ultipor GF-HF filters provide a good solution due to their high voids volume and low pressure drop. Finally, if no air dryer is installed, a liquid/gas coalescer can be installed to remove humidity from the air.

Final or sterile air filtration removes microorganisms from air or other gases, protecting food and beverage products, ingredients, packaging and equipment surfaces from airborne microbial contamination. Pall provides the Emflon® family of validated membrane cartridge filters to address the critical air/gas sterilizing filtration needs in the food and beverage industry.