Classical sheet filtration and stacked disc methods of filtration continues to be well represented in the wine industry. Wineries today consistently meet the demand for supplying top quality wines using lenticular modules and membrane filter cartridges as the final filtration steps prior to bottling. With enclosed designs and their capability for adsorption, surface and depth filtration, filter sheet-based modules enable particle, colloidal haze and bacteria reduction to maximize protection of downstream membrane filters while maintaining the highest possible wine quality.

-

Challenge

-

Solution

-

Results

A large producer of premium bottled wines was using classical stacked disc modules as a prefilter for the final membrane cartridge filters in the bottling lines. The winery was observing problems with handling their classical stacked disc modules such as discs falling apart during dismantling from the housing and module deformation during use. Additionally, the customer was unhappy with the limited total throughputs and service life.

Classical stacked disc module represents the earliest lenticular module design with performance disadvantages like modules deformation and inability to withstand reverse pressure or backflushing.

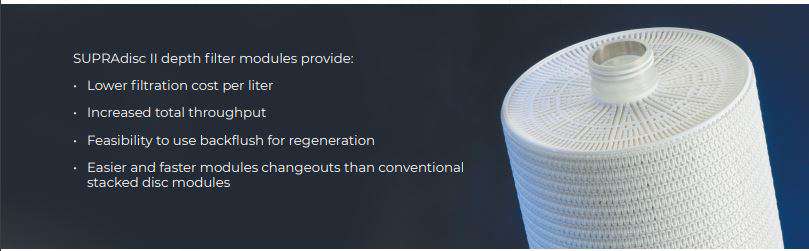

Pall Corporation recommended testing SUPRAdisc II filter modules to facilitate better handling, increased process safety and higher total throughput by using a backflush procedure. Four 12” SUPRAdisc II depth filter modules, type SUPRAdisc II SD200X900C232SPW, were installed in the filtration line for prefiltration of wines.

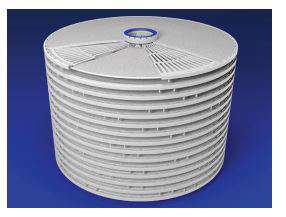

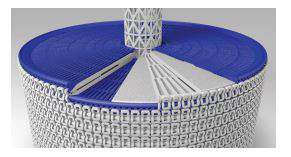

With a dual plate or inside/outside separator design as shown on the left, SUPRAdisc II modules are a significant improvement on the stacked disc design and can be used as an advancement in classical stacked disc and sheet filtration applications.

As with the legacy modules, the SUPRAdisc II filters were used in process until they achieved a differential pressure of 3.0 bar. With the existing modules, once this differential pressure was achieved, the modules were typically clogged and could not be regenerated. However, with the SUPRAdisc II modules, after the filtration run, the modules were backflushed with cold water and forward rinsed with hot water (about 60-65 °C (140-149 °F)) for regeneration which proved successful. Upon restart of the filtration, the customer achieved an initial differential pressure of only 0.3 bar so they could continue on with filtration. As a result of these trials, the winery standardized on SUPRAdisc II Modules, implemented backflush to regenerate the modules in the process, and is now able to achieve up to 40% higher total throughput which significantly reduces OPEX.

In summary, SUPRAdisc II modules meet customer requirements for improved capacity and process safety. The innovative design characteristics based on the inside/outside separator technology are the ky to unique filtration performance, easy handling, higher process safety and the possibility to use backflush procedures to improve total throughput.

Ready to learn more? We can help find the right wine filtration solution for your needs. Contact us.