Ready to learn more? We can help find the right wine filtration solution for your needs. Contact us.

Wine Clarification: Why It’s Essential for Quality and Shelf Stability

Wine clarification is a critical step in the winemaking process that ensures visual brilliance, stability, and consumer appeal. As wine evolves from fermentation to bottling, it can develop unwanted hazes and sediments. These visual imperfections, while often harmless, can negatively impact the perception of quality.

To address this, winemakers use a range of wine clarification and stabilization techniques to remove suspended particles, enhance clarity, and extend shelf life.

What Causes Sediment and Haze in Wine?

Understanding the sources of instability helps highlight the importance of clarifying wine:

- Post-Fermentation Sediment: Includes dead yeast cells (lees), grape skins, seeds, and tartrate crystals.

- Ageing Hazes: Result from interactions between proteins, tannins, and polysaccharides.

- Cold Temperature Instability: Leads to tartrate crystal formation, especially in white wines, which can resemble shards of glass.

Wine Clarification Methods: Choosing the Right Approach

There are several effective wine clarification methods, each suited to different production scales and wine styles:

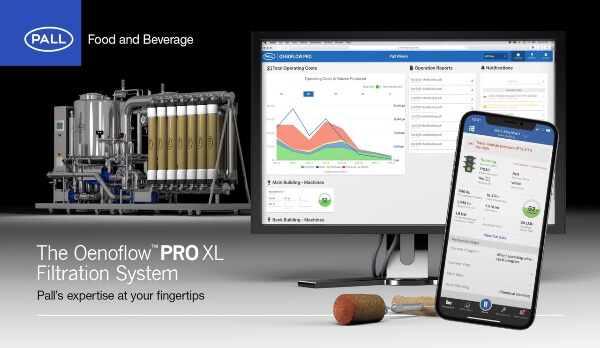

Integrated Wine Clarification Systems

Advanced systems like Oenoflow offer a single-step solution for both wine stabilization and clarification. These systems help reduce production costs, minimize wine loss, and ensure consistent quality across batches.

Evaluating Wine Clarification Methods

| Crossflow | Flat Sheets | Lenticular Modules | Diatomaceous Earth (DE) Filtration | Disk Stack Centrifuge | Settling by Gravity | |

|---|---|---|---|---|---|---|

| CAPEX | 3 | 1 | 1 | 2 | 4 | 1 |

| OPEX | 2 | 3 | 3 | 4 | 4 | 3 |

| Hygiene | 1 | 3 | 2 | 3 | 3 | 3 |

| Footprint | 3 | 3 | 2 | 4 | 3 | 1 |

| Filtrate Clarity | 1 | 2 | 2 | 3 | 5 | 2 |

| Product Losses | 1 | 4 | 3 | 5 | 3 | 3 |

| Changeover/Set-up Time | 1 | 3 | 2 | 4 | 3 | NA |

| Oxygen Pickup | 1 | 2 | 1 | 3 | 3 | 1 |

| 1 = low/good 5 = high/poor | ||||||