Maximizing Chemical Yield in CIO2 Generators Through Best Practices

Chlorine dioxide (CIO2) is the most widely-accepted bleaching agent used in the environmentally-preferred ECF chemical pulp bleaching process.

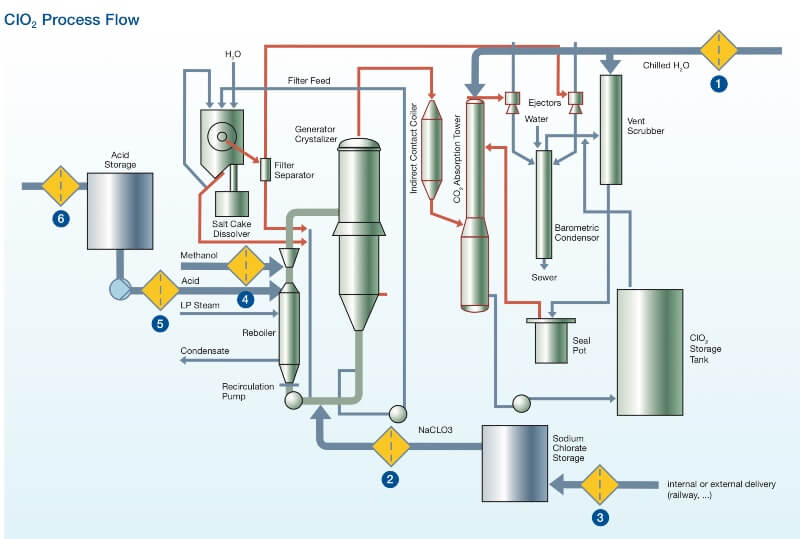

CIO2 is usually manufactured in-situ to avoid instability and prevent gas decomposition according to the following reaction:

Sodium Chlorate + Reducing agent + Acid -> Chlorine dioxide + By-products.

To maximize the chemical yield and reduce safety exposure, the CIO2 generator must be operated according to the best practice procedures. Feedstock contamination is often cited by operators as one of the most unpredictable root causes of variation in their operations.

Based on our experience, the contamination is most likely to come from the acid feed, water dilution, or Sodium Chlorate and less from the reducing agent methanol.

Chlorine Dioxide Generator Operation Needs

- Improve safety conditions by limitation of personnel exposure to hazardous substances

Avoid or limit all CIO2 decomposition for safety reasons and prevent all ‘puffing’ events

Increase CIO2 generator yield to either have lower raw material consumption or produce more CIO2 and then debottleneck bleaching operations

Protect generator from chemical feed quality variation

Limit variation of the CIO2 generation plant, to run the process in as stable as possible operating conditions

- Reduce operator exposure to the off gases from decomposition during puffing event and also exposure and contact with high concentration sulphuric acid during maintenance operations

- Tend and operate reactor toward optimal conditions: for example, Sodium Chlorate consumption to produce CIO2 based on Methanol reducing agent is theoretically of 1,64t of Chlorate to produce 1t of CIO2 with R10 type of reactor.

- Avoid and limit all contamination ingression in the generator (chemical feeds, stock and piping corrosion, intermediate storage release...) as this contamination will react with the strong oxidizer compound CIO2 and therefor reduce the yield of the reactor

- Limit foaming and antifoaming chemical usage as this leads to operations variation and unstable conditions

- Protect your equipment. For example, Acid pumps (unloading or transfer between storage and headtank) are often mentioned as ‘high maintenance cost’ equipment.

Improved Reliability, Efficiency and Effectiveness.

Pall Ultipleat® filters are designed to improve the reliability, efficiency, and effectiveness of pulp and paper bleaching chemical machinery. The crescent-shaped pleat design allows for a large amount of filter surface area to be packed into a smaller space. This allows it to be up to 50% smaller than comparable filter systems, helping bring down maintenance and installation costs.

Minimize Waste Disposal

More, Ultipleat® filters require up to 40 times fewer elements to change out, have higher flow rates per filter cartridge, are coreless and have an all-plastic construction to minimize waste disposal, are absolute rated filter medium for reproducible performance, and have inside-to-outside flow configuration so all debris stays within the filter.

Minimize Waste Disposal

More, Ultipleat® filters require up to 40 times fewer elements to change out, have higher flow rates per filter cartridge, are coreless and have an all-plastic construction to minimize waste disposal, are absolute rated filter medium for reproducible performance, and have inside-to-outside flow configuration so all debris stays within the filter.

Pall Ultipleat® High Flow and Marksmann® Filter Systems are ideal for pulp and paper bleaching chemical filtration needs.

Pulp bleaching generator and paper chemical preparations require pure chemicals to ensure a high-quality product. We provide filter solutions to help ensure high-quality outcomes at high efficiency and low cost.

For more information on improving the efficiency of your processes, contact our team of filtration experts.

Pall Ultipleat® Filters

Our Products

Leading the Industry with product solutions that fit your customers needs.