Efficient Removal of electrolyte mist from green hydrogen at low pressure

January, 2024

Atmospheric alkaline electrolysis is one of the most established green hydrogen technologies. Utilized by major electrolyzer manufacturers and deployed in many upcoming large-scale projects, it offers a mature solution for sustainable hydrogen production.

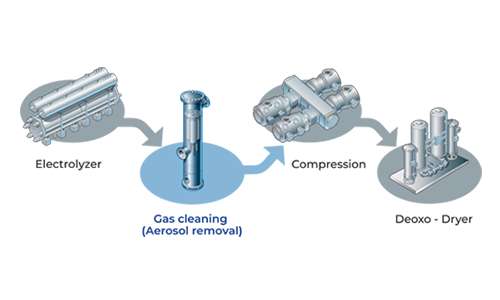

The hydrogen produced in this process occurs slightly above atmospheric pressure. Hence, pressure is at a premium and any further processing of the hydrogen needs to be carried out with minimal pressure drop. For hydrogen producers, this can be particularly challenging, especially with regards to removing electrolyte mist/aerosols from hydrogen leaving the electrolyzer. The electrolyte mist is highly corrosive and if not removed, can cause corrosion and fouling in downstream equipment like compressors and valves.

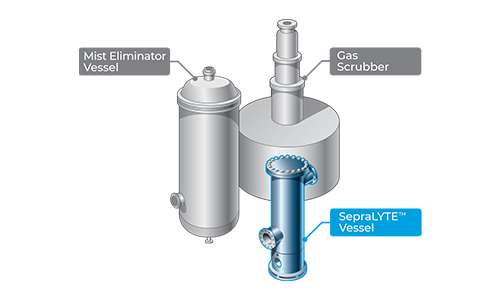

Due to the constraint on pressure drop, the current separation methods available to hydrogen producers, such as mist eliminators and scrubbers, tend to be very large, significantly driving up the capital expenditure (capex) costs of green hydrogen projects.

To tackle this issue, Pall Corporation has launched SepraLYTETM - a new liquid-gas coalescer designed for the green hydrogen market that will achieve liquid droplet separation at low differential pressure, in a compact design.

SepraLYTE liquid/gas coalescers offer considerable advantages over existing conventional separation products:

| Needs of Green H2 producers | SepraLYTETM | Mist Eliminator | Scrubber |

|---|---|---|---|

| Low Relative Operating ΔP | ✔ | ✔ | ✔ |

| Small Size / Footprint | ✔ | ✖ | ✖ |

| Low Energy Consumption | ✔ | ✔ | ✖ |

| Insensitivity to “Turn-Down | ✔ | ✖ | ✔ |

The main advantage that SepraLYTE liquid gas coalescers bring is the significant reduction in overall size. This helps green hydrogen producers reduce the installation and operating costs of their projects via reduction in the volume of steel used, ease of material handling and transportation.

Capex reduction

Benefits for SepraLYTE’s compact design

Experience the future of green hydrogen technology with SepraLYTE. Visit our SepraLYTE webpage to learn more and discover how Pall Corporation can enhance the performance of your Green Hydrogen project. Contact us today!

Subscribe to our blog to stay up-to-date on the latest insights and trends

- Category

- Author

- Sort By