SUPRAdisc™ II Filtration Modules

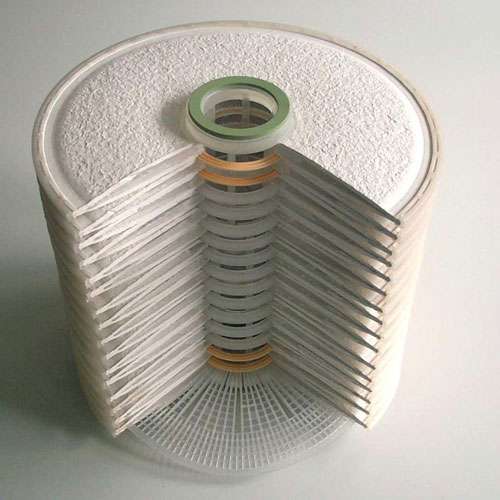

Inside-outside separator technology in a filter block design

What is SUPRAdisc™ II?

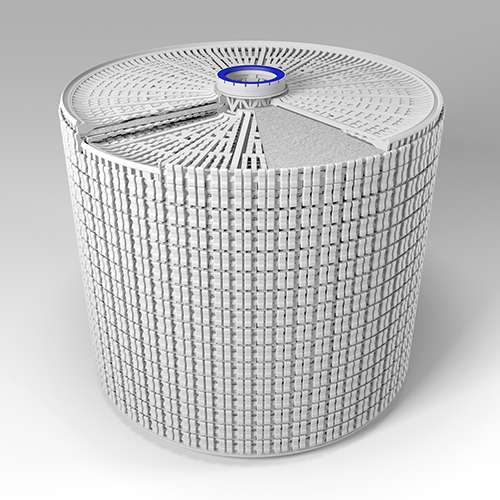

SUPRAdisc™ II Modules are our modern evolution of traditional lenticular depth filter designs used in food and beverage processing. They combine established depth media performance with an enhanced module structure to support stable, consistent filtration. The SUPRAdisc II format helps maintain reliable clarity, manageable product losses and familiar operating principles for breweries, wineries, distillers and ingredient producers.

SUPRAdisc II modules are designed to deliver consistent filtration quality, reduced product loss, and easier handling while maintaining the familiar operating principles of our longstanding depth filtration technologies.

SUPRAdisc II modules use inside outside separator technology to support stable flow, protect media integrity and maintain effective filtration performance

Why SUPRAdisc II?

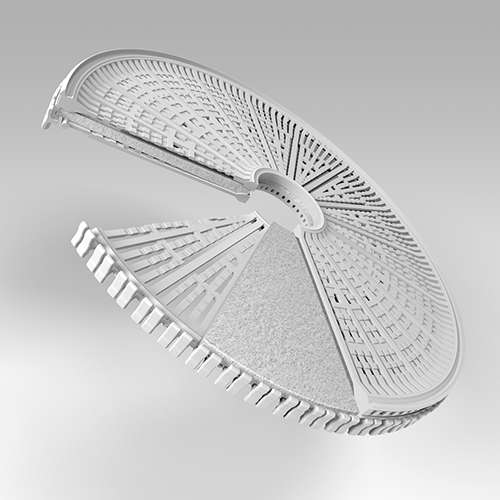

SUPRAdisc™ II Modules use a reinforced block design that improves mechanical stability and supports consistent depth media performance. This integrated structure helps reduce channeling or bypass seen in earlier lenticular formats and maintains reliable module integrity during installation, operation, steaming, and regeneration. It also enables safe, straightforward handling and consistent assembly into Pall SUPRA housings for dependable filtration across food and beverage applications

| Feature | Benefit | Value |

|---|---|---|

| New design with separator technology |

|

|

|

| |

|

| |

|

| |

| Drainable, low hold-up volume assembly |

|

|

| Reliable filtration |

| |

Backflush option |

|

|

| SUPRAdisc housing design | In comparison to plate and frame filters:

|

|

-

Standard Sheet Media

-

Ion-Reduced Sheet Media

-

Pure Cellulose Sheet Media

-

Case Studies & Instructions for Use

Filter sheets available in multiple grades to support microbial reduction and fine, clarifying, or coarse filtration in food and beverage applications.

SUPRAdisc II X Series

- Offered in grades suitable for microbial reduction and fine, clarifying, or coarse filtration.

SUPRAdisc II T Series

Designed for coarse filtration with a coarse pore structure and strong particle holding capacity. The low filtration resistance makes them suitable for viscous media and for retaining gel particles or coarse dispersed components.

Ion reduced filter sheets engineered to support spirits applications requiring very low extractable ion levels. These sheets help manage components that contribute to haze or precipitation in distilled products.

SUPRAdisc II C Series

- Undergo proprietary treatment to achieve very low extractable ions.

- Selectively remove mid and long chain fatty acid esters and particles associated with chill haze in spirits.

- Support consistent filtration results in spirits containing tannins, esters, proteins, or metal complex compounds.

Sheet media made from highly fibrillated pure cellulose, produced without inorganic materials such as DE or perlite. Designed for gentle filtration of premium beverages requiring low ion release.

SUPRAdisc II ZD Series Depth Filter Modules

- Pure cellulose depth media developed for beverage filtration without DE or perlite.

- Provides filtration performance that preserves the sensory quality of high value products.

- Minimizes impact on color and aroma during processing.

- Offers reliable sealing characteristics to support low drip loss in classical filter presses.

Explore application resources, technical documentation, and instructions supporting the use of SUPRAdisc™ II modules across food and beverage processes.

-

New SUPRAdisc II Broch:FBSUPRADISCENb

Download:

-

SUPRAdisc II: Instructions

Download:

How SUPRAdisc II modules are assembled and installed in SUPRA housings for stable filtration performance.

Frequently Asked Questions

What is the purpose of the SUPRAdisc™ II block design?

The block design helps maintain module rigidity and supports consistent depth media performance during installation, operation, steaming, and regeneration. It also reduces risks such as channeling or bypass seen in earlier lenticular formats.

How does the inside outside separator technology work?

SUPRAdisc™ II uses separator technology within each module to improve flow distribution and support stable filtration while protecting the media from damage common in older lenticular designs.

Are SUPRAdisc™ II modules compatible with SUPRA housings?

Yes. The integrated block structure is designed for secure, consistent assembly in Pall SUPRA filter housings.

What filtration applications are SUPRAdisc™ II modules used for?

They are used broadly across food and beverage processing, including beer, wine, spirits, juice, and ingredient filtration.

What sheet media options are available for SUPRAdisc™ II modules?

SUPRAdisc II modules are available with multiple filter sheet types including Standard, Ion Reduced, and Pure Cellulose media, each offered in various grades for fine, clarifying, coarse, or specialized filtration.