Join the brew crew! Contact us below to speak to one of our experts.

Colloidal Beer Stability for Optimum Shelf Life

Today consumers expect a beer with a long shelf life free of changes in clarity and appearance. Colloidal stability, in addition to microbial stability, is the main influencing quality criteria for a sufficient shelf life of packaged beer.

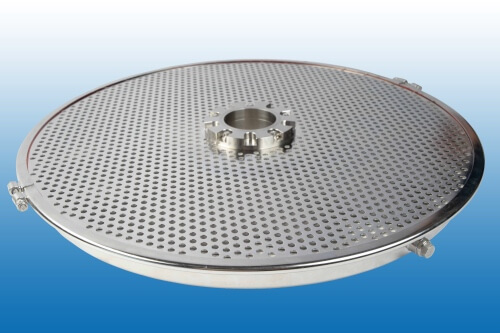

The newly developed Pall CBS (Continuous Beer Stabilization) system is a flexible polyphenol stabilization solution for batch and continuous operation, providing precise stabilization effectiveness combined with reliable colloidal beer stability at the lowest cost and negligible beer losses.

Why is beer stabilization important?

Pall's Continuous Beer Stabilization (CBS) System combines proven materials for beer stabilization (PVPP) with new technology, enabling continuous stabilization of all kinds of beer. The latest development with CBS is beer IoT-based digitalization, which allows more advanced process control and optimization. This new CBS technology perfectly balances optimum colloidal beer stability with minimum change in beer composition.

The compact design with a throughput/volume ratio of 15:1 not only results in rapid switching between brands but also significantly reduces beer and beer extract losses, ensuring a cost-effective operation.

Oxygen pick-up is kept to a minimum from the start due to the compact design and seamless switch between de-aerated water and beer at the process start, end and brand changes, ensuring the highest quality of beer.

The CBS system is designed to be compact, occupy a smaller footprint, require low investment costs, and improve operational costs. The smaller system hold-up reduces chemical, water, and energy consumption and eliminates the need for CIP tanks. The CBS System covers a production range between 100 to 900 hl/h and provides flexible handling of varying stabilization.

IoT in the brewing process - Impact on Performance and Consumption | The implementation of IoT in the beer-making process supports transforming the industry towards sustainable and cost-effective production. With IoT based digitalization in filtration and stabilization, breweries can optimize processes, automate machine learning, and manage data for reporting, traceability, and analysis.

But IoT users have one primary concern in common – data security. Pall values data security as the highest priority and proactively takes all the necessary steps to remain best-in-class. Therefore, it is essential that the latest state-of-the-art technology protects brewery data with penetration tests and code scanning exercises to continuously identify risks and takes the necessary actions to ensure brewery data remains where it’s needed.

Through Pall BeerIoT, brewers can optimize their operations, improve sustainability and quality initiatives, and improve their OpEx. |

CBS IoT | To gain maximum advantage from the data generated by a CBS control system Pall implemented IoT-based real-time data management with constant access to valuable information across the organization in user-defined formats. The ability to benchmark against other installations within a brewery group and against the industry average is also available. |

Examples of digital data analytics |

|

Documentation and service data | Pall IoT provides direct online availability of all system-specific documentation and training documents, spare parts lists, service reports, operating instructions, safety instructions and acceptance reports. |

Looking for something else? Discover other beer filtration solutions here: